Choosing the Right Gasket Material for Tri-Clamp Connections: A Comprehensive Comparison of Buna-N, Viton, and PTFE

Share

Understanding Gasket Materials for Tri-Clamp Connections: Buna-N, Viton, and PTFE

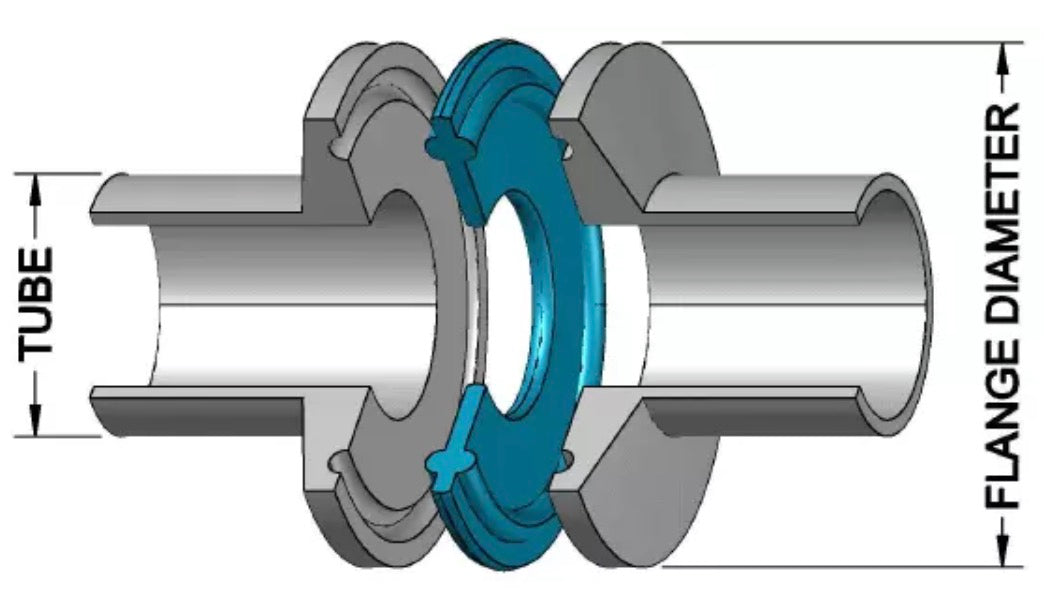

Tri-clamp connections are the backbone of industrial piping systems, facilitating the seamless transport of liquids, gases, and solids. These connections rely on precision components: two ferrules, a gasket, and a clamp to secure them. Among these, the gasket plays a critical role as the sealing element, preventing leaks and ensuring a reliable fit. Selecting the right gasket material is essential, as each type offers unique properties tailored to specific applications. In this post, we’ll break down three popular gasket materials—Buna-N, Viton, and PTFE—evaluating their temperature ranges, chemical compatibility, pricing, and longevity to help you make the best choice for your operations.

Buna-N Gaskets: Affordable and Reliable for General Use

Buna-N (nitrile butadiene rubber) gaskets are a cost-effective option with excellent mechanical properties and strong resistance to oils and water. Operating within a temperature range of -40°F to 212°F (-40°C to 100°C), they’re ideal for low to moderate temperature applications.

Key Features of Buna-N Gaskets:

- Chemical Compatibility: Works well with butane, propane, alcohols, and ethanol. Not suitable for ketones, esters, or aromatic hydrocarbons.

- Durability: Moderate lifespan; not recommended for prolonged high-temperature exposure.

- Price: Economical, making it a great choice for cost-sensitive projects.

- Best Uses: Low-pressure systems, oil and water applications, and general-purpose setups.

Viton Gaskets: High-Performance in Tough Conditions

Made from fluoroelastomer, Viton gaskets are built for demanding environments. With a wide temperature range of -40°F to 400°F (-40°C to 204°C), these gaskets excel in high-temperature and chemically intense applications.

Key Features of Viton Gaskets:

- Chemical Compatibility: Excellent resistance to a broad spectrum of chemicals, including butane, propane, alcohols, ketones, esters, and aromatic hydrocarbons.

- Longevity: Long-lasting and highly resistant to compression set, maintaining shape and sealing integrity under stress.

- Price: Higher upfront cost but offers better value over time due to its durability.

- Best Uses: Applications requiring high-temperature resilience and resistance to diverse chemicals.

PTFE Gaskets: Superior Chemical and Temperature Resistance

PTFE (polytetrafluoroethylene), often recognized as Teflon, is a premium choice for extreme conditions. These gaskets can withstand temperatures ranging from -100°F to 500°F (-73°C to 260°C) and are chemically inert, offering unmatched versatility.

Key Features of PTFE Gaskets:

- Chemical Compatibility: Handles virtually all chemicals, including acids, bases, solvents, and hydrocarbons.

- Durability: Long lifespan, lasting up to a decade with proper maintenance.

- Price: The most expensive of the three but provides excellent value for critical applications.

- Installation: Requires precise seating during installation; not recommended for high-pressure systems due to low tensile strength.

- Best Uses: Extreme temperature and aggressive chemical environments.

Comparison Table: Choosing the Right Gasket for Your Needs

| Parameter | Buna-N | Viton | PTFE |

|---|---|---|---|

| Temperature Range | -40°F to 212°F (-40°C to 100°C) | -40°F to 400°F (-40°C to 204°C) | -100°F to 500°F (-73°C to 260°C) |

| Chemical Resistance | Good with oils and water; fair with alcohols | Excellent with a wide range of chemicals | Chemically inert, resistant to most chemicals |

| Price | Low | Moderate to High | High |

| Longevity | Moderate | Long | Long |

| Installation | Easy | Easy | Requires precision seating |

| Best Applications | General-purpose, low-cost projects | High-temperature and chemical-heavy setups | Extreme conditions, specialty environments |

Final Thoughts: Picking the Right Gasket

Each gasket material serves a specific purpose, so understanding your application’s requirements is crucial.

- Choose Buna-N for affordability and reliable performance in low-temperature applications.

- Opt for Viton if durability and high-temperature compatibility are priorities.

- Invest in PTFE for maximum chemical resistance and versatility in extreme conditions.

For high-quality tri-clamp gaskets and industrial components, check out our extensive selection of American-made products. We pride ourselves on providing dependable, cost-effective solutions tailored to your needs.

Shop gaskets and more here to ensure your system performs at its best!